3B’s contributing technology recognized in the JEC Innovation Award 2014 – Sustainability category

3B SE3030 glass roving offers enhanced fibre/resin adhesion through an optimized sizing, resulting in improved composite properties that ensure long-lasting blade operations.

In order to offer competitive products to the market, wind turbine manufacturers need blades with low weight, high stiffness, and excellent resistance to fatigue, enabling a long and efficient working life.

A new-to-the-world composite system is being evaluated by Siemens Wind Power for its next generation wind turbine blades. This system was introduced by DSM and 3B, with support from DTU Wind Energy and offers easy resin infusion and processing, and excellent fibre/ resin interaction yielding superior static and fatigue strengths.

The system is based on DSM’s Beyone™ 201-A-01, a resin that is styrene-free, cobalt-free and 40 % bio based with performance that can compete with traditional epoxy systems. These enhanced performances are obtained when used in combination with 3B’s SE3030 glass fibres.

3B SE3030 sizing is tuned for new styrene free resins and leads to:

- a perfect wet out and laminate quality,

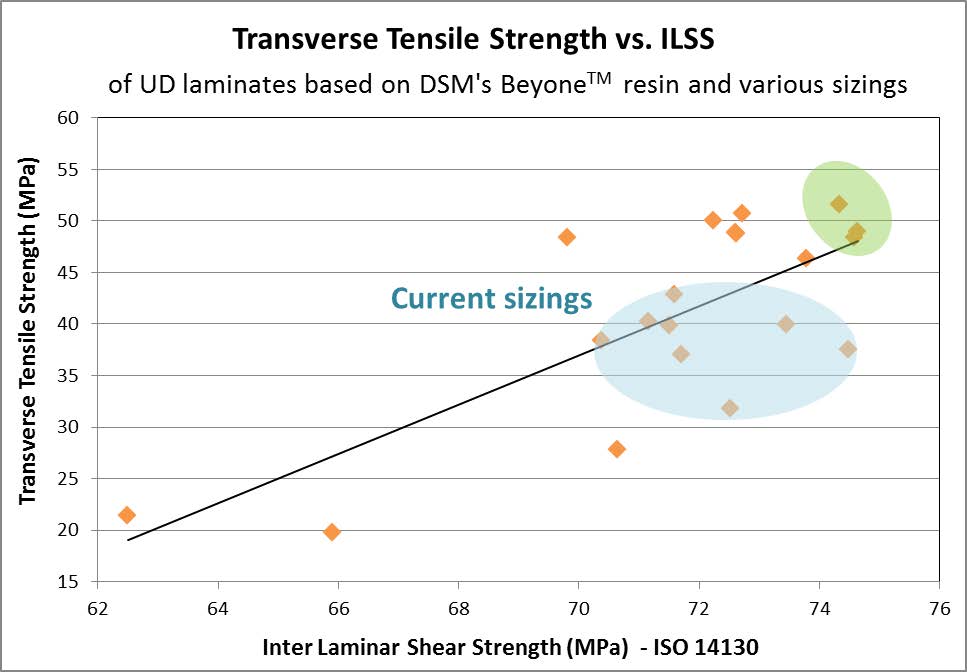

- Improved Inter Fibre properties with transverse tensile strength superior to 50 MPa,

- Enhanced fatigue performances by more than 10x versus traditional sizings meeting the benchmark non Polyester systems for the Wind Energy market

- Improved Inter Laminar Shear Strength

For wind turbine manufacturers, the new composite system provides many benefits, including a major reduction in blade manufacturing cost, a better working environment, an increased process output thanks to significantly shorter cycle times and a sustainable material solution. 2 | P a g e

In order to commercialize new technologies that have the potential to revolutionize the manufacturing of wind turbine blades, it was required to think out-of-the-box and form a strong channel partnership. 3B, DSM, Siemens Wind Power and DTU were able to demonstrate that, through co-creation, a complex technology can be developed at record speed.

Luc Peters, 3B Wind Energy Technical Leader, comments: “The use of 3B SE3030 roving optimized for styrene free resin is delivering enhanced performance versus commercially available sizing.

The optimization of this sizing has been achieved thanks to an open technical exchange and brainstorming between the resin experts from DSM and the sizing developers from 3B. This also illustrates 3B’s innovative approach: build on our expertise to develop new glass and new sizing technologies to design better value, greener and higher performance solutions in close partnerships with our customers.

With the support of renowned labs such as DTU (Risoe) and industrial partners such as Siemens Wind Power, we made sure we were on the right track during the whole development phase. The outcome is a unique green system that was unthinkable a couple of years ago.”

3B together with DSM, Siemens and DTU have been presented the JEC Innovation Award in the Sustainability category.