ACTING TO LIMIT CLIMATE CHANGE IS OUR RESPONSIBILITY

The search for solutions to limit the company's impact on the environment is at the heart of 3B's development. Over the years, reducing our emissions has been a priority and we have achieved very good results. Our main lines of actions so far:

-

operating with a glass formulation designed to limit discharges, since 1995

-

optimising combustion technologies for ever greater energy efficiency

-

continuously improving production and supporting processes for limited waste generation and emissions

-

investing in waste reduction and recycling.

CO2 Emissions

CO2 emissions are a major environmental impact of glass fibre manufacturing because the glass melting process requires a lot of energy. Today, 3B is working intensely on its strategy to achieve carbon neutrality by 2050 at the latest.

As per the Green House Gas (GHG) protocol GHG emissions can be divided in 3 scopes:

• Scope 1: Direct emissions corresponding to emissions related to fossil fuel consumption and decarbonation of raw material

• Scope 2: Indirect emissions related to purchased electricity

• Scope 3: Indirect emissions related to purchased goods, transport, services

Our 0 carbon strategy includes actions on each scope.

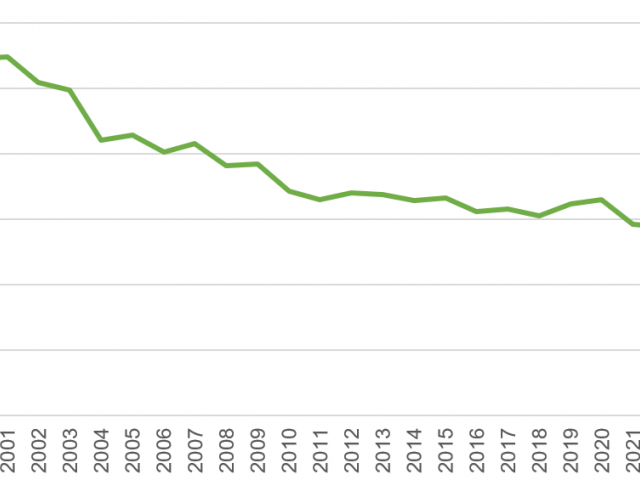

Direct CO2 emissions (GHG Protocol Scope 1)

With regards to direct CO2 emissions major efforts have been made over the last decades to implement state-of-the-art melting technologies which have resulted in a decrease of direct CO2 emissions of 45% in 2022 vs 2000.

Indirect CO2 emissions - electricity (GHG Protocol Scope 2)

The use of renewable electricity is now a major part of our sustainability strategy, with each 3B plant working according its own local integration.

In Norway, 98% of the produced electricity is of renewable origin. Our plant is also a member of the Birkenes Wind Cluster and Wind Innovation Centre, which is supporting the development of a local 85 MW wind farm.

In Belgium, in Battice, several projects are under study to source a larger portion of renewable electricity thanks to specific projects near the plant. Installation of photovoltaic panels is ongoing.

Indirect CO2 emissions - purchased goods, transport, services (GHG Protocol Scope 3)

Scope 3 emissions account for approximately 52 % of the carbon footprint of our products.

Important contributors are the production of raw materials as well as inbound and outbound transport. 3B is intensifying its collaboration with suppliers and logistics partners to improve the visibility and accuracy of the carbon footprint of the purchased products and further decrease its CO2 footprint. 3B also strives to reduce the footprint related to logistics:

- permanent watch over technology and solutions for new sustainable logistics alternatives around our plants

- screening of suppliers based on sustainability criteria, green vehicles, …

- optimisation of packaging solutions (bulk, higher loading, …)

- multimodal logistics options (rail, water, heavy liner).

Energy efficiency

Reducing energy consumption and optimising energy efficiency is a top priority for 3B. Driving down energy consumption reduces impact on resources, related pollution and the overall CO2 emissions.

By continuously improving our melting technologies, 49% specific energy consumption reduction has been achieved globally over the last decades (measured in MWh/T melted glass).

Read 3B's Sustainability reports for more detailed information

3B Sustainability Report 2022

This report covers the year 2022 and relates 3B's work on sustainable development in environmental, social and governance terms.

3B Sustainability Report 2021

Year on year sustainability journey for 3B

3B Sustainability report 2020

3B Sustainability Report 2019

3B Sustainability report 2018

Our Sustainability report covers the year 2018, as part of our Communication on Progress (United Nations Global Compact - Signatory).

3B Sustainability report 2017

3B-the fibreglass company is a member of the United Nations Global Compact initiative since 2015. Yearly Sustainability report 2017.

3B Sustainability Report 2016

Sustainability for 3B is... “A pre-condition to be a long-term successful, ecological and socially responsible leader in the glass fibre market.”